The Influence Mechanism of Polyacrylamide on the Flowability of Cement Slurry

Abstract:

This article studies the influence of polyacrylamide (PAM) on the flowability of cement slurry, tests the particle size distribution of cement particles, rheological parameters of cement slurry, and the adsorption rate of cement particles on water-reducing agents, and analyzes the mechanism of PAM influence. The results show that a trace amount of PAM can significantly reduce the flowability of cement slurry. PAM promotes the flocculation of cement slurry and increases its viscosity, which is the main cause of the poor flowability of cement slurry.

Keywords: Polyacrylamide; Polycarboxylate superplasticizer; Cement slurry; Flocculation; Plastic viscosity.

In order to meet the requirements of GB/T 14684-2022 "Construction Sand" for the content of stone powder in the mechanism sand, the stone powder can be removed by washing the mechanism sand. However, this will generate a large amount of washing wastewater containing stone powder. In order to avoid polluting the environment, sand-making enterprises usually use coagulants to treat the washing wastewater and recycle the upper layer of clear water for sand washing again. Therefore, a certain amount of coagulant will remain on the surface of the mechanism sand particles and in the moisture content of the mechanism sand.

Polyacrylamide (PAM for short) is a commonly used coagulant for washing wastewater. The residual and accumulated coagulant in the recycled water for washing mechanism sand will seriously affect the performance of the prepared concrete. In recent years, quality problems in concrete due to residual coagulants have occurred. Researchers have found that when the PAM coagulant content exceeds 0.1‰, the fluidity of mortar gradually decreases with the increase of the coagulant dosage. Experts have also studied the correlation between PAM concentration in mixing water and the fluidity of cement slurry and slump of concrete. The results show that with the increase of PAM concentration in mixing water, the fluidity of cement slurry and the slump of concrete decrease. Therefore, it is suggested that the PAM concentration in mixing water should not exceed 0.03%. When the residual coagulant in the mechanism sand is too high, the viscosity of the concrete mixture increases, the fluidity decreases, and the loss of fluidity increases, which will lead to a certain degree of strength reduction in the concrete.

Currently, most research focuses on the adverse effects of PAM coagulants on the fluidity of mortar and concrete. However, there is relatively little exploration of the mechanism behind these effects. This paper aims to investigate the mechanism of the impact of PAM coagulant on the fluidity of cement slurry by testing the particle size distribution of cement, the rheological properties of the slurry, and the adsorption properties of the water reducer in PAM-containing cement slurries. The ultimate goal is to provide a reference for the scientific application of PAM coagulants in the production of mechanism sand.

1. Experiment Overview.

1.1 Raw Materials and Mix Proportion.

Cement: P.I 42.5-grade reference cement for concrete admixture testing, with an apparent density of 3.18 g/cm3, a specific surface area of 338 m2/kg, and a standard consistency water requirement of 27.1%. The mineral composition of the cement is shown in Table 1.

| C3S | C2S | C3A | C4AF | MgO | CaSO4.2H2O | CaSO4.0.5H2O | Amorphous phase |

| 58.5 | 11.8 | 3.8 | 11.9 | 0.5 | 0.9 | 1.4 | 8.4 |

PAM: A powder, anionic type, with a degree of ionization of 25% and a relative molecular weight of 1.8x107. 24 hours before the experiment, PAM was mixed with distilled water to prepare a 1‰ aqueous solution.

Water reducer: High-performance polycarboxylic acid water reducer PCA, with a solid content of 10% and a water reduction rate of 29.4%.

The mix proportion of the cement slurry is shown in Table 2, where "Ref." refers to the control group, and the number after "-" represents the thousandth percentage of PAM relative to the mass of cement.

| No. | Cement | Water | Water-reducing agent | PAM |

|---|---|---|---|---|

| Ref. | 900 | 251.3 |

10.8 | 0 |

| PAM-0.002‰ | 900 | 249.5 | 10.8 | 1.8 |

| PAM-0.005‰ | 900 | 246.8 | 10.8 | 4.5 |

| PAM-0.010‰ | 900 | 242.3 | 10.8 | 9.0 |

| PAM-0.050‰ | 900 | 206.3 | 10.8 | 45.0 |

Ref. No water-reducing agent |

900 | 450.0 | 0 | 0 |

PAM-0.005‰ No water-reducing agent |

900 | 445.5 | 0 | 4.5 |

1.2 Performance Testing.

Flowability Test: According to the ratio in Table 2, weigh the raw materials and add water and admixtures to the mixing bowl at once. Then add cement and start the mixer in automatic mixing mode. The flowability of the cement slurry is tested after the end of mixing, with testing times at 5, 10, 15, 20, 30, 60, 90, 120, and 150 minutes after the start of mixing.

Particle Size Distribution Test: Take 0.2 mL of the cement slurry and drop it into a deionized water sample holder. Turn on the ultrasonic function and continuously test for 2 minutes. Use a dynamic image particle size and shape analyzer to test the particle size distribution of the particles.

Rheological Parameter Test: After the cement slurry is mixed and ended, take a sample after 10 minutes and test the rheological parameters of the cement slurry using a soft-solid rheometer. Prepare Polyacrylamide aqueous solution by mixing water and PAM according to the ratio in Table 2, and test the rheological parameters of the Polyacrylamide aqueous solution using a soft-solid rheometer. The working program of the rheometer is shown in Figure 1, and the testing data of shear stress and shear rate collected within 200~260s are analyzed for rheological performance.

Adsorption rate test: Samples of approximately 25 mL are taken from the cement slurry at 5, 10, 15, 20, 30, 60, 90, and 120 minutes after the start of mixing, and placed in a centrifuge. The centrifuge is operated at 10,000 r/min for 2 minutes, and then 0.2 g of the upper clear liquid is taken and mixed with 1.0 g of 1 mol/L hydrochloric acid. Finally, deionized water is added to a total weight of 20 g, and the organic carbon content of the sample is measured using a total organic carbon analyzer to calculate the adsorption rate.

2. Results and Discussion.

2.1 Effect of PAM on the Fluidity of Cement Slurry.

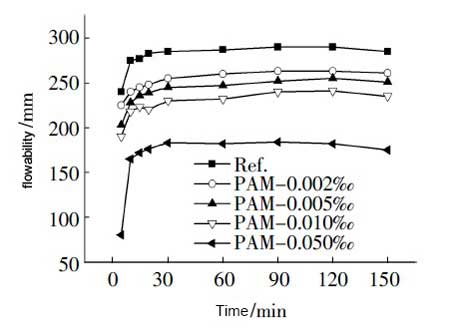

The effect of PAM on the fluidity of cement slurry is shown in Figure 2 and Figure 3.

Based on figures 2 and 3, it can be observed that the addition of PAM significantly reduces the flowability of the cement slurry, and the reduction becomes more pronounced with increasing PAM dosage. The flowability decreases almost linearly with increasing PAM dosage. When the PAM dosage is the same, the flowability of the cement slurry increases rapidly in the first 20 minutes and then remains relatively stable, except for a slight decrease trend for the PAM dosage of 0.050‰. The time-dependent changes in the flowability of the cement slurry after the addition of PAM did not show significant correlation with the PAM dosage.

2.2 Influence of PAM on Particle Size Dstribution in Cement Slurry.

The influence of PAM on particle size distribution in cement slurry with and without superplasticizer is shown in Figure 4 and Figure 5.

Figure 4 and Figure 5 show that when the PAM dosage is 0.005‰, the particles in the cement slurry with a particle size greater than 120 μm increase, indicating that PAM promotes the agglomeration of cement particles into larger particles. Agglomeration and dispersion are two opposite mechanisms. Agglomeration causes the particle size to increase and the particle movement ability to decrease. The water and water reducer inside the agglomerated body are difficult to exert the dispersion effect, resulting in a decrease in the flowability of the cement slurry. The agglomeration mechanism of PAM is more significant in an environment without water reducers, while it is slightly smaller in an environment with water reducers.

2.3 Analysis of the Rheological Properties of PAM Aqueous Solution and Cement Slurry.

The rheological properties of PAM aqueous solution and cement slurry are shown in Figure 6 and Figure 7.

As shown in Figure 6 and Figure 7, with the increase of PAM concentration, the plastic viscosity of the PAM aqueous solution increases. When the PAM concentration reaches 0.050‰, the PAM aqueous solution exhibits the phenomenon of picking up and slowly breaking off. The plastic viscosity of the cement slurry also increases significantly with the increase of PAM dosage.

Non-adsorptive viscosity-modifying agents increase water viscosity, thereby increasing the viscosity of cement slurry. In contrast, PAM-type adsorptive viscosity-modifying agents adsorb multiple cement particles with long-chain structures, causing cement particles to bond and string together, thereby increasing the viscosity of cement slurry.

It can be seen that the increase of PAM concentration leads to the increase of the viscosity of PAM aqueous solution and the formation of a flocculated structure of multiple cement particles through the long-chain structure, ultimately resulting in the increase of the viscosity and the decrease of the fluidity of the cement slurry.

2.4 The effect of PAM on the adsorption properties of water reducers.

The effect of PAM on the adsorption performance of water reducer is shown in Figure 8.

The impact of PAM on the adsorption performance of water-reducing agents is shown in Figure 8. It can be seen from the figure that adding PAM can significantly increase the early adsorption rate of cement particles to water-reducing agents. Compared with the Ref. group without PAM, when the PAM dosage is 0.010‰, the adsorption rate at 5 min increases by 6.7%, at 10 min increases by 8.6%, and at 15 min increases by 6.6%. The adsorption rate of a water-reducing agent by cement particles increases with the increase of PAM dosage. This is because PAM promotes the formation of large-scale flocculated particles of cement particles, and the water-reducing agent adsorbed inside the flocculated particles has little effect on the fluidity of the cement slurry, reducing the amount of water-reducing agent available for dispersing cement particles and causing a decrease in the fluidity of the cement slurry.

2.5 Comprehensive Mechanism Analysis.

The study found that the adsorbed water reducer in the cement slurry exists in two forms: part of it plays a dispersing role on the surface of cement particles, and the other part enters the interior of the hydration products to form organic-inorganic mineral phases, which has no positive effect on the flowability of the cement slurry. It can be concluded that the high adsorption rate of water reducer on cement particles does not make the cement slurry have better flowability, indicating that PAM promotes the formation of large-sized agglomerates in the cement slurry, leading to a much greater degree of degradation in flowability caused by PAM than the beneficial effect of the water reducer. In addition, the agglomerates induced by PAM in the cement slurry may also consume a large amount of water reducer, causing the effective adsorption of water reducer on cement particles to decrease, ultimately resulting in a decrease in the flowability of the cement slurry due to the comprehensive effect.

In practical production, the decrease in concrete fluidity caused by residual PAM in the manufactured sand can usually be restored to meet the construction requirements by increasing the dosage of a water-reducing agent (30%~80%). This also proves to some extent that PAM can cause a partial loss of effectiveness of the water-reducing agent, leading to a decrease in the fluidity of the cement slurry.

3. Conclusion.

(1) PAM significantly reduces the flowability of cement slurries with added polycarboxylate superplasticizers. The degree of deterioration of the flowability is greater at lower PAM dosages (0.002‰~0.005‰), but no significant effect of PAM on the time-dependent changes in the flowability of the cement slurry was observed.

(2) The flocculation effect of PAM leads to a significant increase in the number of large-size particles and flocculation bodies with particle sizes above 120μm in PAM-added cement slurries, which is unfavorable for the flowability of the cement slurry. The number of large flocculation bodies is slightly reduced when adding a superplasticizer to the cement slurry.

(3) PAM increases the plastic viscosity of cement slurries, and the flowability of high-viscosity cement slurries is significantly reduced.

(4) PAM significantly increases the early adsorption of superplasticizers on cement particles, and the adsorption of superplasticizers inside the cement particle flocculation body is unfavorable for the flowability of the cement slurry.